Tungsten Disulfide Powder- A Powerful Dry Lubricant To Dispense Lubricity To The Appliances

Tungsten Disulfide Powder | Img Source : cdn11.bigcommerce.com

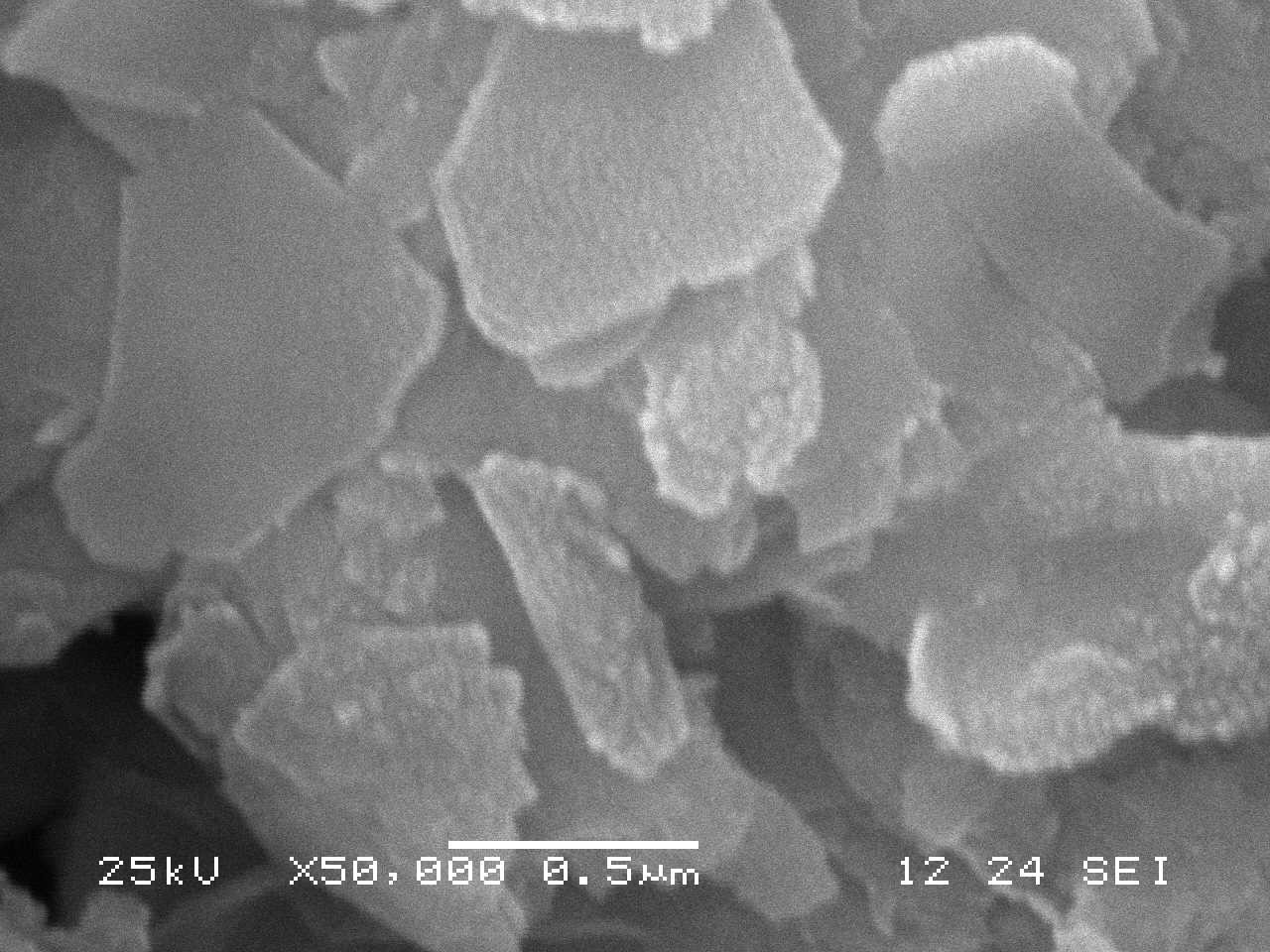

Tungsten disulfide powder or WS2 is a dry or solid lubricant powder that is considered the most lubricious material in the world of science. The substance is bearing a high quality of dry lubricity with a low friction coefficient, lesser than the other substances like graphite or Teflon. This is why Tungsten disulfide can be a better option than Molybdenum Disulfide or MoS2. The inorganic chemical compound (Tungsten disulfide) with a hexagonal crystal structure helps to reduce the noise tendency of machines with accurate lubrication.

How Tungsten disulfide powder is useful?

The lubricant is highly effective even under the higher temperature and pressure measures with its resistance property.It works in a sustainable atmosphere under the temperature range from -450⁰F to 1200⁰ F or -270⁰C to 650⁰C. Although in a vacuum it can resist from -305⁰ F to 2400⁰ F or -188⁰ C to 1316⁰ C.Even though the load tolerance power is extremely high of the coated layer by 300,000 psi. Due to the low coefficient of friction of 0.07 static and 0.03 dynamic, the combined applications are vast and can be tried with varied combination coatings for corrosion protection.

Here are the three of the best ways WS2 powder can be applied for the surface coating:

1) Mixture of WS2 powder with oil, grease, or synthetic type of wet lubricant-

1 part of powder can be mixed with the 15 parts of the wet lubricant. The process will increase the lubricity of the mixture with the enhanced tolerance power of extreme temperature and pressure during application. With the use of mixture, WS2 makes the coating on the movable components of the machinery and that reduces the friction rate between the surfaces with the improved lubricity. Through the mixture, the weight or load holding capacity gets enhanced for a longer period with flawless functionality.

2) Coating the WS2 powder without a binder

The Tungsten disulfide powder can create a coating by spraying the surface with cool and dry atmospheric air at 120 psi. At room temperature,the spraying process will be done without any binder. The coated layer of WS2 will be of 0.5-micron thickness. The coating will help various areas of automotive components and other machine engines to get lubricated with the lifetime application ability.

3)Combination of WS2 powder with Isopropyl alcohol

In this application process, WS2 powder will be mixed with the Isopropyl alcohol and the mixture will be coated to the surface. There is a variety of applications on different surfaces of this mixture like Aerospace components, ball bearings, Roller and linear bearings, etc., on the marine parts, cutting appliances, valve parts, blades, knives, etc.Even though it’s highly effective on mold release and precision gears and pistons with a lot more other machinery parts in the industrial sector.