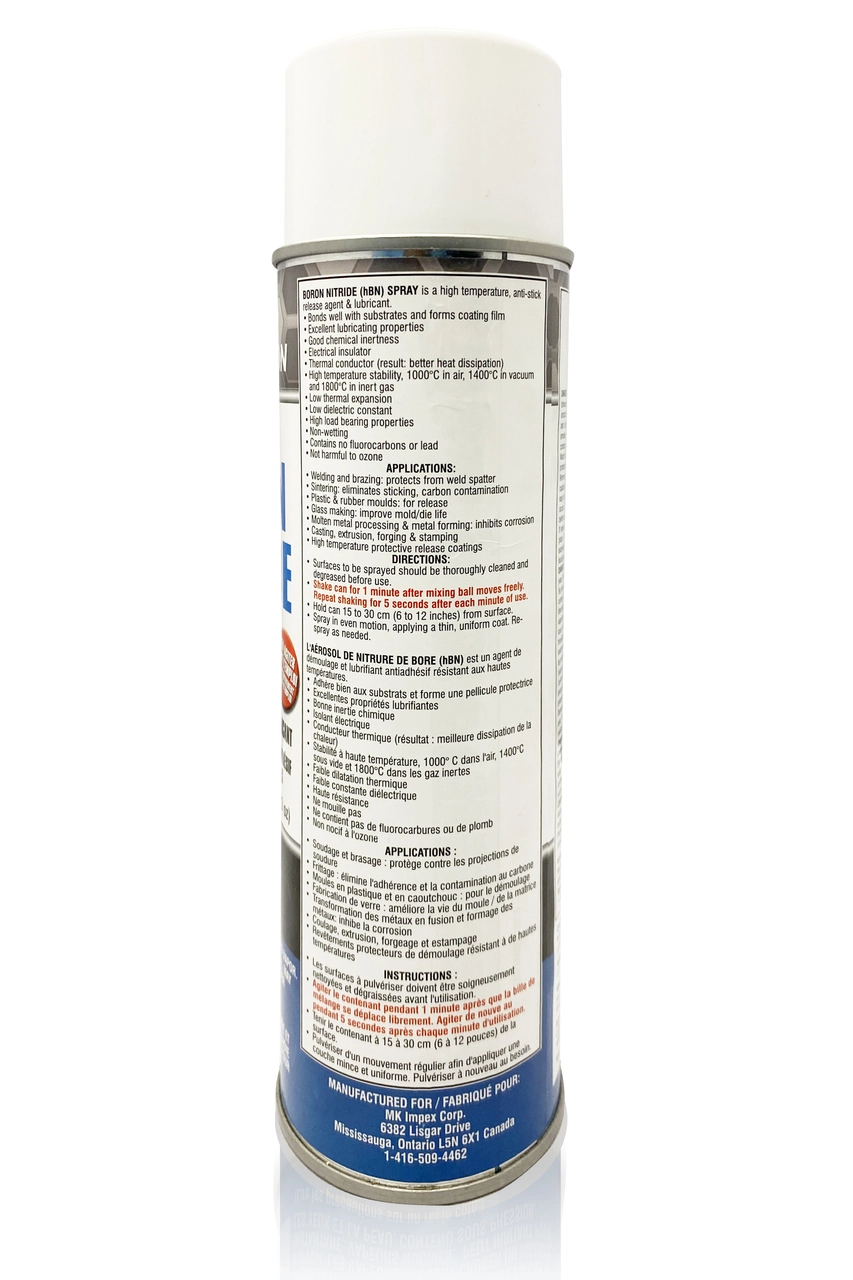

A Look Into The Special Features And Qualities Of Boron Nitride Aerosol Spray

Boron Nitride Aerosol Spray | ishanblogs-99.webselfsite.net

When you look into the many available dry lubricants on the market, one that is sure to stand out is Boron Nitride. It can be applied to the moving parts of machinery to protect them against the wear and tear caused by friction. Such moving parts work for long hours, and so, over a period of time, they can easily get damaged. Applying a dry lubricant is essential in order to give them long-lasting performance and ensure that they are always in top performing condition. It also helps in preventing expensive repair costs that can bring industrial operations to a standstill.

Why Make Use Of Boron Nitride Aerosol Spray?

In industries, machines work at high temperatures, some more than others. In such machines, using oil or grease will not do as their state will change under such temperatures. In such situations, boron nitride’s exceptional ability to resist high heat makes it an ideal lubricant. It can be applied to the metal parts of such machinery so that they perform optimally. The lubrication process will continue even under extreme temperatures that are not capable of being managed by traditional lubricants. This dry lubricant can also be applied to ceramics, plastics, alloys, and rubber to improve their lubricating properties. Here is a look at the different forms of Boron Nitride:

• Hexagonal – It finds numerous applications due to its high lubricating ability, thermal stableness and also ability to conduct electricity

• Cubic – It has good electrical resistance, thermal conductivity and is a sound abrasive material

• amorphous – This is the non-crystalline form of boron nitride and it has structure and properties similar to carbon

• Nanotube – it is similar in structure and properties to carbon and possesses high electrical insulation, heat and also chemical stability

Boron Nitride Aerosol Spray can be easily applied on the surface of various metal parts quickly and conveniently. It quickly sticks to the surface, providing it with lifelong protection from wear, heat, chemicals, and rust. It can be mixed with a lubricating oil to enhance its coefficient of friction, thus bringing down the potential for wearing out. In materials such as rubber, alloys, ceramics, and plastic, it is boron nitride that carries out the function of improving existing lubricating properties. When it is mixed with any lubricating oil, it enhances its coefficient of friction, thus enabling it to drastically reduce the wear out caused by friction.